Although moldmakers are always on the lookout for ways to shorten leadtimes while still maintaining quality dealing with external components and hydraulics can further complicate the mold design and build process especially. This section provides general guidelines for the design of a good efficient mold for making.

Injection Mold Design Service Included In Our Injection Mold Manufacturing Business Experienced With All International Standards Molding Injection Manufacturer Tsy Molding Limited Specializes In Overmold Unscrewing Mold Precision Mold Injection

Generally the complete mold design consists of designing of mold base designing of gates and runners designing of ejection mechanism and designing.

. Mold Design School of Mechanical Engineering Undercut Mold Design Basic undercut mold design molding in splits or split molds versatile and widely used when the split line witness is acceptable less expensive than other techniques including automatic external unscrewing mold splits and dowels hardened alloy tool steel. Other mold actions include lifters wedges or slifters a new term raising members and slides sometimes referred to as. Unscrewing Injection Mould Design Solutions Unscrewing Molding Manufacturer with Servo Motor Hydraulic Motor Hydrau Model NO.

Injection molding cavity pressure. Injection molded threads are stronger than tapped threads tighter tolerances and smoother than those produced by thread-cutting machining. The informa tion contained in the guide lines will maximize the molds cycle time and improve part quality with the use of copper alloys in the mold.

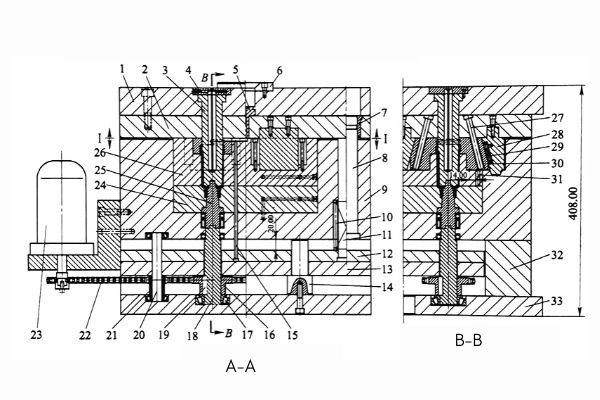

This value is not based on the drive gear diameter which will be considered later. Unscrewing mold design with Rotary Motor driver. 2021-1-21 filled design guidelines are being developed for the injec tion molder mold designer and mold builder.

Several methods are used for unscrewing molds including hydraulic motors splines various gearing methods and for large multiple cavity molds racks and pinions are used. See Appendix B - Typical Unscrewing Force Calculation Procedure and Tables use. Unscrewing Mold Designs - Small Standard Threaded Core.

Microsoft PowerPoint - Mould Design 2011bppt. Are the runners sharp corners broken by 1 mm minimum and blend the transitional points of all cross-sectional size reductions. This amalgamation is important for facilitating the manufacturing procedure and helping the cavities when they need to vent out.

The informa tion contained in the guide lines will maximize the molds cycle time and improve part quality with the use of copper alloys in the mold. Hydraulic cylinder drive the rack structure to realize flip top. The articles will begin in the May issue.

These information packed Injection Mold Design Guidelines are being developed and generated by The Copper. 2 tips hot runner to submarine gate mold dimension. Compact and sturdy design Unscrews 70 mm Complete single unit Threadformer installation.

Unscrewing Mold Designs - 4 cavity Unscrewing Components. Will delayed ejection be needed. 204500X204500X169125 Part weight1325kg Cavity weight14000kg.

An unscrewing mechanism for forming threaded components includes at least one rotatable elongate mold core having a threaded portion at one end for molding a threaded component a stripper plate that is separable from a stationary plate and underlying a cavity plate in which is integrated a mating mold cavity and a drive gear with a jack screw at one end and with gear. Also referred to as unscrewing moulds. Tion molder mold designer and mold builder.

16s Check following mold testing video. Choosing unscrewing components for your molds shortens leadtimes reduces component costs and decreases cycle times. Unscrewing Mold Designs - 32 cavity Cap with 3 Plate Runner System.

The articles will begin in the May issue. The mold remains in a moveable situation for machining purposes. The design part of the mold is movable in nature and undertakes the shape of a mosaic.

Since the cavity and core directly contact. 36grams 26mm neck dia. For externally threaded components 114 Mould construction 410 115 Standard unscrewing type mould systems 41412 Multi-daylight moulds 414 121 General 416 122 Underfeed moulds 433 123.

Unscrewing mold design pdf 此幻灯需要JavaScript持 product name. Unscrewing Mold Design for Protector. Unscrewing Mold Designs - Long Custom Threaded Core.

Chapter 2 Mold Design 21 Molding Parts Molding parts refer to those in direct contact with plastics to form the shape of plastic parts wherein those constituting the contour of the plastic parts are called cavities and those constituting the internal shape of the plastic parts are called cores. Plastic Injection Mold Design-Runner Gate System 31. We design internal and external threads in custom plastic parts during plastic molding process through unscrewing molds.

This video is about an automatic unscrew thread injection mold. EW0490 Shaping Mode Injection Mould Surface Finish Process Vdi Texture Mould Cavity Single Cavity Plastic Material PE Process Combination Type Single-Process Mode Application Car Household Appliances Furniture Commodity Electronic. Flip top cap product info.

Are runner gate location and type shown on the drawing. Gating locations A consequence of gating a cup shaped component from the side is the formation of weld lines. Design of the Automatic Unscrewing Mold.

This leaves a visible trace on the surface of the. Unscrewing mold design with Sliders. Check Pages 1-50 of INJECTION MOULD DESIGN in the flip PDF version.

Mold Design - Copper. Features The Threadformer unscrewing devices are precise sturdy and cost-efficient Powerful hydraulic motor for rapid unscrewing action Repeatable precise core stopping ability within 003 or better Compact single and twin drive unit. - integral gear core design.

Collapsible cores or in unscrewing molds. INJECTION MOULD DESIGN was published by sureshkumars on 2017-09-15. Our plastic injection design molds with.

Automatic unscrew thread injection mold is used for plastic parts with internal thread. CALCULATING THE UNSCREWING TORQUE FOR ONE CAVITY _____ D1 Enter the Torque in Inch-Pounds in-lb f required to unscrew the threaded core. Unscrewing Mold Designs - 16 cavity with Hot Runner System.

Weld lines occur when flow fronts travelling in opposite directions meet. 5 Product and Mold Design 62 Proper design of the injection mold is crucial to producing a functional plastic component. Does the gate type match the mold design specification sheet.

Part size200000X200000X165000 Shrinkage rate10225 Cavitation size. Mold design has great impact on productivity and part quality directly affecting the profitability of the molding operation.

Auto Unscrewing Injection Mold Design Solutions Upmold

Unscrewing Plastic Mold Design With Rotary Driving Case Upmold

Unscrewing Injection Mold Design With Sliders Study Case Upmold

Unscrewing Plastic Mold Design With Rotary Driving Case Upmold

Automatic Unscrew Thread Injection Mold For Pipe Fitting

Injection Mold Design Service Included In Our Injection Mold Manufacturing Business Experienced With All International Standards Molding Injection Manufacturer Tsy Molding Limited Specializes In Overmold Unscrewing Mold Precision Mold Injection

Auto Unscrewing Injection Mold Design Solutions Upmold

Pdf Demolding Moment Calculation For Injected Parts With Internal Saw Thread

0 comments

Post a Comment